Professor Chengxin Wang's team realizes voltage-tailorable room-temperature Ca-metal batteries

Source: School of Materials Science and Engineering

Edited by: Tan Rongyu, Wang Dongmei

Ca-metal batteries, as one of the most promising energy storage technologies beyond Li, are showing wide prospects due to the wider natural abundance of calcium, lower redox potentials and smaller effective ion-radius (ion radius divided by weight or charge) comparable to lithium, and better environmental compatibility. However, the application of Ca-metal batteries is challenged by the fast decay of Ca plating/stripping and Ca-ion insertion/extraction electrochemistry, as well as their slow kinetics and extremely severe polarization. The reasons lie in that insertion/extraction of Ca-ion involves large Coulomb forces, while the deposition/dissolution of Ca is usually accompanied by severe out-of-control anion corrosion. The former leads to a significance decrease in the energy storage capacity of the cathode, while the latter results in the deactivation of Ca deposit, and on the other hand, device resistance increases geometrically due to the formation of insulative layers of CaF2 and CaH2. In general, the application of Ca-metal batteries lacks suitable cathodes with high capacity, and feasible electrolytes, together with stable electrode-electrolyte interfaces, to ensure stable Ca plating/stripping process with relatively weak polarization shifts.

To solve these problems, professor Wang et al. from School of Materials Science and Engineering, Sun Yat-sen University, for the first time introduced a multi-ions electrolyte optimization strategy, with the help of different solvation properties of various ions and more compact encapsulation of multi-ions derived hybrid solid electrolyte interphases (HSEI), to effectively reduce the polarization barriers and prohibit the deposit from anion corrosion, so as to tailor the polarization potentials for Ca-plating/stripping. At the same time, they also developed the method to fabricate graphitic fibric carbon membrane cathodes by cellulose waste paper. The cathodes delivered excellent performance for high-capacity Ca-based energy storage and good wide window voltage adaptability (output an energy density of 517.5 Wh kg-1 at 100 mA g-1, good voltage adaptability between 0.005 and 4.9 V) benefitted by enhanced energy storage capacity from multi-ions of different sizes and new type energy storage mechanism of Anion-Cation Relay Storage (Small Science, 2021, 1, 2000030). Those virtues together lead to the high-performance voltage-tailorable Ca-metal batteries (as illustrated in Figure 1, 2).

Figure 1. Ca-metal batteries based on electrolyte optimization strategy and graphitic fibric carbon membrane cathode.

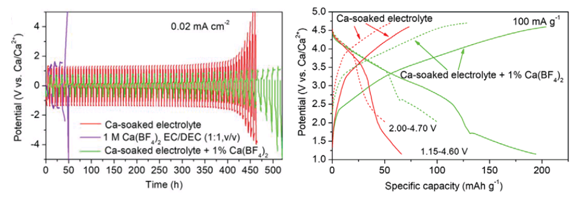

Figure 2. Tailoring the Ca-plating/stripping potentials and device voltages based on electrolyte optimization strategy, potential-time tests for Ca//Ca symmetrical cells (left), and voltage profiles for Ca-metal batteries (right) before and after optimization.

In this work, the polarization of Ca//Ca batteries was reduced by 0.65 V through the multi-ions electrolyte optimization strategy, ensuring better stability of Ca-plating/stripping (>400 h). Combining the special membrane cathode, the Ca-metal batteries deliver reversible capacity of 101 mAh g-1 at 2.0-4.7 V and 100 mA g-1, holding an average output voltage of 3.2 V and a capacity retention of 77% after 100 cycles. This is another innovation after the previous work—high voltage Ca-metal batteries (Advanced Materials, 2021, 33, 2006141). It was published as a Front Cover article in Advanced Energy Materials, titled “Multi-ions Electrolyte Enabled High Performance Voltage Tailorable Room-Temperature Ca-Metal Batteries”. Huawei Song, a research fellow, was the first author, and Prof. Chengxin Wang was the corresponding author. The work was financially supported by the National Natural Science Foundation of China and the Basic Scientific Research Fund of Sun Yat-sen University.

Link to the article: https://onlinelibrary.wiley.com/doi/10.1002/aenm.202003685

Link to the cover: https://onlinelibrary.wiley.com/doi/10.1002/aenm.202170037